Fire Fighting Ductile Iron Grooved Pipe Flange and Fitting

Basic Info

| Model NO. | VT19050701 |

| Quality | High Quality |

| Size | as Per Customer′s Requirments |

| Transport Package | Poly Film and Carton |

| Specification | As Per Customer′ s Requirments |

| Trademark | Weldo |

| Origin | Guangdong, Dong Guan |

| HS Code | 84669300 |

| Production Capacity | 100000PCS/Month |

Product Description

Fire Fighting Ductile Iron Grooved Pipe Flange and FittingBasic Info

| Model NO. | VT19050701 |

| CNC Machining or Not | CNC Machining |

| Type | Broaching, Drilling, Etching / Chemical Machining |

| Inspected | 100% Inspected Before Delivery |

| Sample Time | Within 3-5 Days |

| Surface Finishing | Anodizing, Polishing, Plating, Blacken |

| Transport Package | Poly Film and Carton |

| Origin | Guangdong, Dong Guan |

| Name | Fire Fighting Ductile Iron Grooved Pipe Flange and Fitting |

| Material Capabilite | Aluminum, Brass, Bronze, Copper, Hardened Metals |

| Keyword | Flange and Fitting |

| Size | As Per Customer′s Requirments |

| Bulk Lead Time | 15-20 Days |

| Trademark | Weldo |

| Specification | SGS, ISO9001 |

| HS Code | 84669300 |

Fire Fighting Ductile Iron Grooved Pipe Flange and Fitting

Introduction for CNC machining part:

Dong Guan Weldo Precision Machining Co.,ltd, which is a manufacturer specializing in the machining parts with rich manufacturing and design experience.

Our products include: gringing parts, machining parts, turning parts, lathe parts, milling parts, CNC milling parts, CNC machining parts, CNC turning parts, CNC lathe parts, CNC metal parts, stamping parts, casting and forging parts, assembly service, laser cutting parts, flange and fitting, die casting parts, metal stamping parts, gear and transmission, aluminum profile, automation group, punch parts, and all kinds of custom/customize parts.

Welcome to send us your drawing for CNC parts machining service, we can customize as your requirement.

Some photos for CNC Machining part:

Our Experience for CNC Machining part:

We are with rich experience in processing of various materials,

such as AL6061/7075, SUS303, 304, ESD225/420, DERLIN, SI36H, SS440C,17-4 ph, Ceramic, Carbide,Engineering Plastics such as PEEK and so on. In addition, we can also provide some special processing, special heat treatment and special electroplating, surface treatment for customer, such as optical grinding, honing, precision EDM specialshaped processing, carburizing, nitriding, vacuum heat treatment and cryogenic treatment, the hard anodized aluminum, steel blue, electrolytic polishing, nickel sank without electricity,silver-plated, gold-plated and so on.

Material: Copper,iron,aluminum,stainless steel,alloy steel,plastic.etc.Which we usually processing are as following show.

Technical parameter of CNC Machining part:

| 1.Material | Aluminum, Brass, Bronze, Copper, Hardened Metals |

| 2.Tolerance | +/-0.05mm |

| 3.Finishing | anodizing,polishing,plating ,blacken ect |

| 4.Edges and holes | debarred |

| 5.Surfaces | free of scratches |

| 6.Material capabilities | aluminum, stainless steel, copper, plastic and more |

| 7.Various materials and finishing ways are available | |

| 8.Non-standard aluminum product | |

| 9.Material and finishing comply with RoHS Directive | |

| 10.Small orders are welcome | |

Factory picture for CNC Machining part:

Technical Details of CNC Machining part:

Technical Process | CNC machining, EDM W/C |

Dimension | Client's artwork is available |

Capability | Milling:Length,machining range up to 1100*600 mm |

Turning: Diameter 0.05mm~300mm ; Length 0.5mm ~ 750mm | |

Wire Cutting: machining range can up to 450*400*300mm | |

Precision | Turning and Milling:+/- 0.002mm(+/-0.000098 inch) |

Wire Cutting: +/- 0.002 mm (+/-0.000098 inch) |

Equipment List for making CNC Machining part:

| Equipment List | ||||

| Name | Quantity (set) | Origin | Precision | Running Distance |

| CNC gantry machine | 1 | China | 0.005mm | 2000*1300mm |

| CNC machining Centers | 1 | China | 0.005mm | 600*500mm |

| CNC horizontal machine center | 4 | China | 0.005mm | 800*500mm |

| CNC machining Centers | 9 | China | 0.005mm | 600*500mm |

| CNC lathe/mill machine center | 4 | China | 0.005mm | 50*150mm |

| Lathe Machine | 2 | China | 0.01mm | 200*750mm |

| Milling Machine | 10 | China | 0.01mm | 300*700mm |

| grinding machine | 3 | Tai Wan | 0.003mm | 150*400mm |

| High Speed W/C | 4 | China | 0.015mm | 250*300*400mm |

| Slow Feeding W/C | 1 | China | ||

| Sand Blast Machine | 1 | China | ||

| Polishing Machine | 1 | China | ||

QA inspection Equipments for CNC Machining part:

| Measuring Equipment | ||||

| Name | Qty(set) | Origin | Precision | W.T |

| Height Gauge | 2 | Swiss | 0.001mm | |

| Microscopy | 1 | China | 0.005mm | |

| Rockwell Hardness Tester | 1 | China | 0.01mm | |

| projector | 1 | Japan | 0.003mm | |

| Aluminum alloy spectrometer | 1 | Germany | ||

| Pull test Machine | 1 | China | 5T | |

Why Choose our CNC Machining part:

1. Fully Machining Services:

Gringing parts , Machining parts, CNC milling and turning parts , CNC milling parts, CNC

metal parts, grinding parts, stamping parts, casting and forging parts, assembly service.

2.Various Machining Materials:

Metal parts, stainless steel parts, alloy steel parts ,brass parts, bronze parts, copper

parts, aluminum parts, plastic parts, ect.

3.Various Finishes:

Anodizing, Electroplating, Polishing, Powder Coating, Blacken, Hardening, Painting and

many other treatment of the parts.

4.Quality Assurance :

IPQC inspect each precision grinding parts during every processing step; 100% inspection before shipment by micrometer, height gauge, projector measuring machine, coordinate

measuring machine(CMM), ect. Any disqualification will be responsible by us.

5.Advantage:

1>.Non-standard/standard/OEM/ODM/customized service provided

2> No MOQ, no quantity limited

3 >Fast lead time

4> Can meet DIN,JIS,ASTM,AISI,BS,GB standard

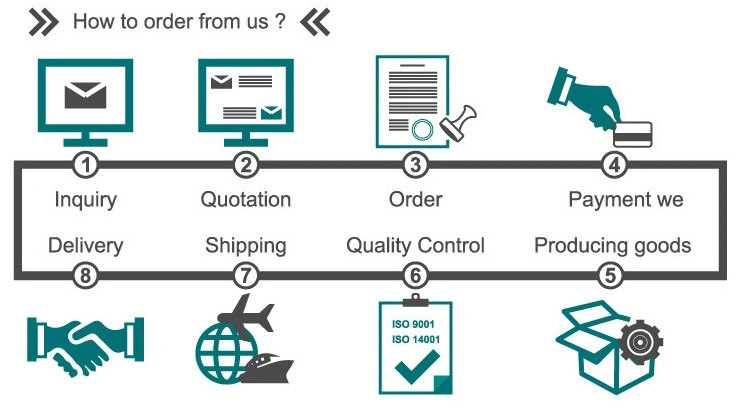

Payment and shipping for CNC Machining part:

After Service for CNC machining part:

Welcome consult with us, we service:

1. Best Solution for your production.

2. Fast delivery for your urgent order.

Contact infomation for CNC Machining part:

Vince Tian

mob:+86 187 7342 8971

Detail material sheet for CNC Machining part:

| Aluminum | 6061-T6,6063-T5,7075-T6,2011,2017,2024,5052,5083,6082,etc |

| Stainless steel | SUS303, SUS304, SUS316,SUS316L, SUS430, SUS440, SUS420, SUS201,etc. |

| Steel | Q235,20#,45#,Cr12,SKD11,A2,40Cr,16Mn,Cr12Mov,etc. |

| Carbon Steel | 1010,1015,1020,1030,1035,1040,1045,etc. |

| Free Cutting Steel | 1211,12L13,12L14,1215,etc. |

| Brass | C11000,C10200,C12000,C26000(HPb59),C36000(C26800), C38500(HPb58, C27200(CuZn37), C28000(CuZn4),etc. |

| Plastic | PVC,PE, PMMA,POM,Telfon,Delrin,PEEK,Nylon, ABS,PC,PP,PA6,PA66,etc. |

Processing method for CNC machining part:

| 1 | CNC Turning |

| 2 | Auto lathe |

| 3 | 3/4/5 axis CNC milling |

| 4 | CNC turning and milling compound processing |

| 5 | Grinding |

| 6 | Fast/midium/slow wire EDM |

| 7 | Wire-Cutting |

| 8 | Welding |

| 9 | Cast |

| 10 | Taping |

| 11 | Drilling |

Surface treatment for CNC Machining part:

| 1 | Zinc/nickel/chrome plating |

| 2 | hot galvanized |

| 3 | painting |

| 4 | powder coating |

| 5 | Anodize Oxidation, or with colors:like silver, blue, red, etc. |

| 6 | plating,silver-plated,Gold-plated,etc |

| 7 | polishing |

| 8 | electrolytic polishing |

| 9 | sank without electricity nickel |

| etc | etc. |

Hot treatment for CNC Machining part:

| 1 | Vacuum |

| 2 | carburizing |

| 3 | nitriding |

| 4 | cryogenic |

More photos for CNC machining part: